Fresh flour in your bakery – from grain to flour

Grain and grain products are the most important basic nutrients for human beings. Not only the complex carbohydrates and the plant protein make grain so valuable. Numerous vitamins, minerals, plant substances and especially fibre can support health and prevent modern lifestyle diseases. Particularly in times in which our food is characterised by fast food and industrial nutrition, many people are thinking again about a nutritious, balanced diet. Fresh wholemeal, gently and softly ground, is the foundation for fluffy bread and pastries.

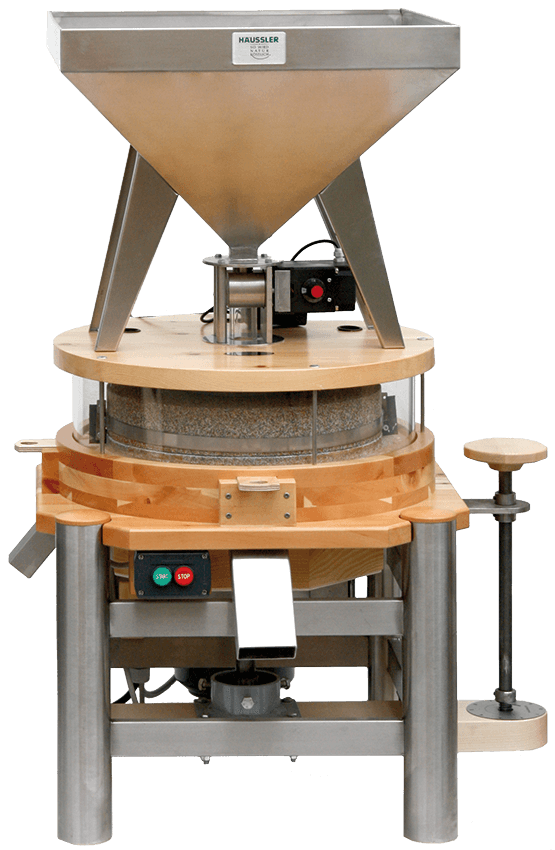

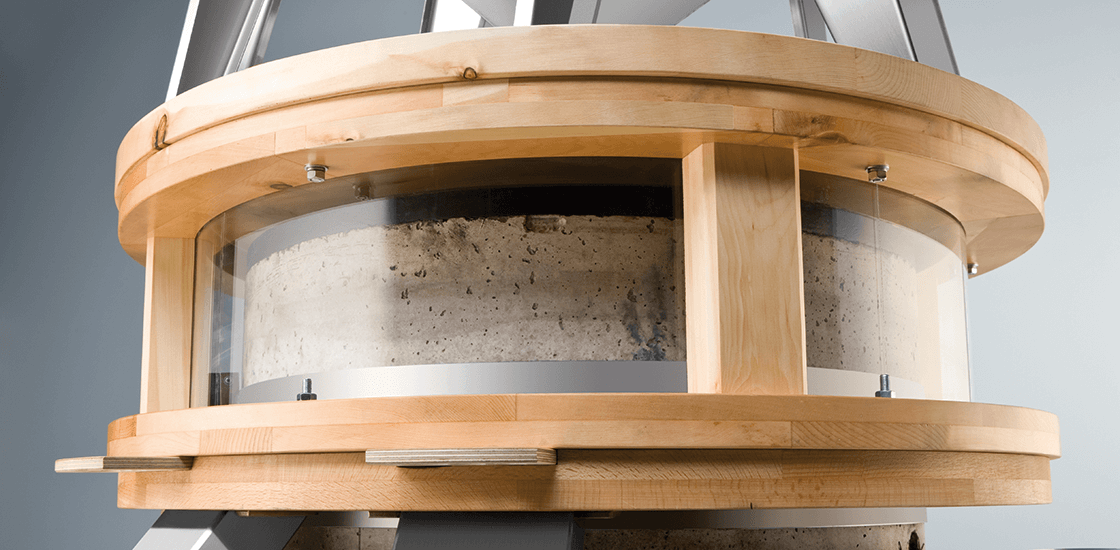

Prerequisite for high-quality wholemeal is using a good grain mill with a stone grinder. Through the interaction of the horizontal millstones, the grains are hulled and very finely ground to maintain the nutritional value at low rpm. All Häussler mills work according to this principle and ensure you an optimum flour quality for your business.

Stone information

In all Häussler mills up to a stone size of 50 cm, a porcelain-bound corundum stone is used. Corundum (the second hardest rock after the diamond) is mixed with ceramic, pressed and fired at high temperatures. The stone thus consists of pure mineral components, without any synthetic additions. The stones are extremely hard, long-lived and resistant.

Naxos stones are built-in, starting with Häussler’s mill size HM 70 N. These stones are comprised of corundum, emery and magnesite. Due to the sharp grinding surface, these stones have a high grinding efficiency and grind the grains to fine granular wholemeal. The stone is resistant, durable and self-sharpening; a sharpening of the stones is not necessary. Further information on the HM 70 N grain mill.

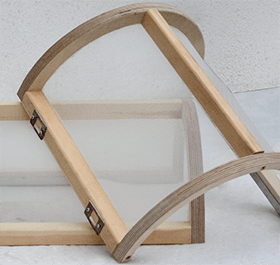

Häussler commercial mills of the HM series are made in a combination of stainless steel and wood. In addition to the attractive design, this type of construction has significant benefits:

the supporting frame is extremely stable and torsion-free thanks to the self-supporting tubular design and low weight. The mill housing and sifting machine are made of stone-pine wood. This has the advantage that no condensation forms and and mould growth is prevented as much as possible. In addition, the stone-pine wood, aromatically scented of resin, has been shown to repel pests. The wood is provided with a natural varnish on the outside and is easy to care for.

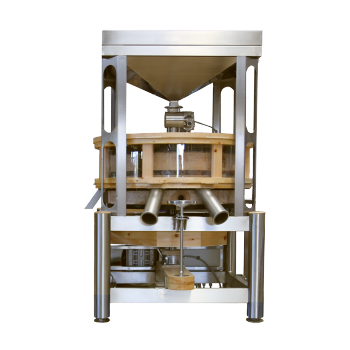

The grinding stones are clearly visible behind glass. As a result, the mill can turn into a real focal point in the customer area.

With the patented electric metering device, the supply quantity of the grain can be perfectly regulated. The upstream natural magnet separates out possible iron pieces.

Due to the low rpm of the grinding stones, the grain is ground to a fleecy soft wholemeal, maintaining its nutritional value, and a warming of the ground product is minimised. The degree of fineness of the flour can be continuously adjusted by means of a handwheel. A subsequent retrofitting of the mills with a flour sifting machine is possible at any time.

Operation and maintenance of the Häussler mills are easy and do not require a lot of time. The mills of the HM series are designed for continuous use and are a durable investment thanks to the high standard of quality.

Gentle grinding principle of the water mills

Häussler grain mills work with a high-quality grinder made of ceramic and corundum. The grinding stone is very hard and as a result virtually wear-free and self-sharpening. The special feature of the grinder is that the grain is not cut or chopped but rather slowly and gently pulverized at low speed. As a result, you obtain a fine wholemeal with all the vitamins, minerals and fibre that are contained in the grain. Ideally suited for baking light and fluffy baked goods.

All types of grain can be ground: wheat, spelt, rye, kamut, emmer, einkorn, barley, maize, rice, millet and buckwheat (also in the hull) as well as conditionally oil-containing seeds.

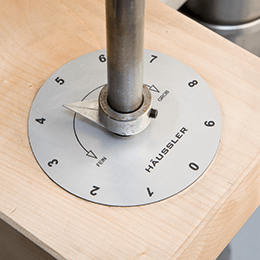

Fineness adjustment

Establish the degree of fineness, from fine flour to coarse meal.

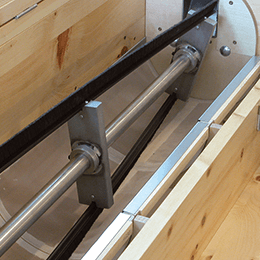

Discharge control by manual slider

Each mill has several outlets, which can be easily operated using a manual slider.

Electric metering device

With the patented electric metering device, the grain supply can be continuously regulated.

Optional with sifting machine

Sifting device with three sieves, which facilitate the separation of flour, semolina and bran.

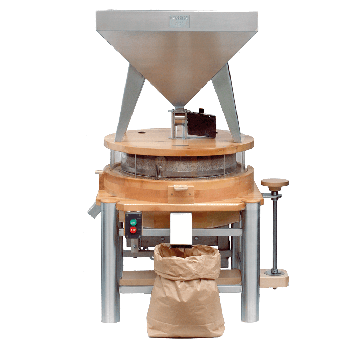

HM Series

The mills of the HM series have a stone diameter from 30 to 70 cm. Whether you want to further process your grain yourself or you would like to offer your customers fresh wholemeal, the HM series provides the appropriate mill for every requirement. The mills can be combined at any time with a flour sifting machine. All the necessary connections are prepared.

Advantages of the HM series

- Ceramic bonded grinders HM 30 P, HM 40 P and HM 50 P

- Patented electric metering device

- Continuous adjustment of the fineness

- Discharge control with a manual slide

- Optional with base frame

- Electrical connection for flour sifting machine, therefore can later be retrofitted at any time

The mills of the HM series at a glance

| HM 30 P | HM 40 P | HM 50 P | |

| Stone diameter | 30 cm | 40 cm | 50 cm |

| Flour output approx. | 20 kg/h | 30 kg/h | 70 kg/h |

| Dimensions W x D x H | 70 x 80 x 98 cm | 80 x 88 x 115 cm | 89 x 100 x 129 cm |

| Weight | 74 kg | 118 kg | 184 kg |

| Hopper contents | 15 kg | 38 kg | 64 kg |

| Motor | 400 V / 1.1 kW | 400 V / 2.2 kW | 400 V / 3.6 kW |

| Stone rotations/min. | 380 | 350 | 300 |

Available in different sizes

HM 30 P

HM 40 P

HM 50 P

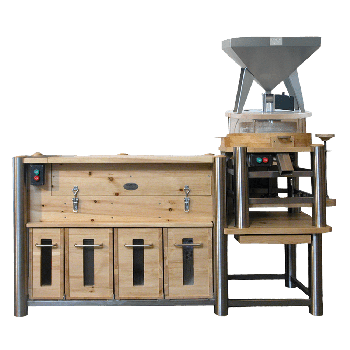

HM combination grain mill with flour sifting machine

The flour sifting machine separates fresh-ground wholemeal into 3 sections, fine flour, semolina and bran, depending on the choice of sifter. The flour sifting machine can be switched on or off at any time.

HM combination grain mill with flour sifting machine

| HM 30 P Combo | HM 40 P Combo | HM 50 P Combo | |

| Dimensions, flour sifting machine, W x D x H | 158 x 59 x 80 cm | 174 x 69 x 86 cm | 200 x 74 x 87 cm |

| Weight, flour sifting machine | 85 kg | 114 kg | 130 kg |

| Motor, flour sifting machine | 400 V / 0.37 kW | 400 V / 0.37 kW | 400 V / 0.37 kW |

| Contents per flour box | 13 kg | 18 kg | 27 kg |

| Overall dimensions W x D x H | 165 x 80 x 142 cm | 189 x 88 x 161 cm | 213 x 100 x 169 cm |

| Total weight, sifting machine | 159 kg | 232 kg | 314 kg |

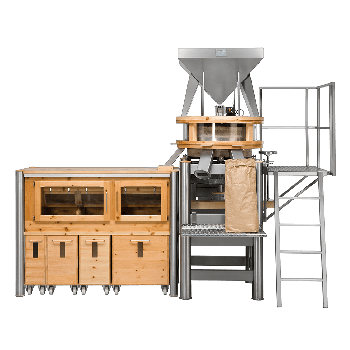

HM 70 N

A Naxos stone is built-in starting with model HM 70 N. This ensures a gentle grinding of the grain even at a higher hourly output.

Technical data HM 70 N

| HM 70 N | |

| Stone diameter | 70 cm |

| Flour output approx. | 100 kg/h |

| Dimensions W x D x H | 122 x 135 x 185 cm |

| Weight | 528 kg |

| Hopper contents | 150 kg |

| Motor | 400 V / 5.5 kW |

| Stone rotations/min. | 250 |

Larger mills

We continue to offer:

| HM 100 N | HM 120 N | HM 150 N | |

| Stone diameter | 100 cm | 120 cm | 350 cm |

| Flour output approx. | 140 kg/h | 180 kg/h | 320 kg/h |

Platform & ladder can be attached in the rear or on the side

The sifting machine separates flour, semolina and bran

HM 70 N Combo

| HM 70 N Combo | |

| Dimensions, flour sifting machine, W x D x H | 275 x 85 x 128 cm |

| Weight, flour sifting machine | 129 kg |

| Motor, flour sifting machine | 400 V / 0.75 kW |

| Contents per flour box | 85 kg |

| Overall dimensions W x D x H | 325 x 135 x 268 cm |

| Total weight, sifting machine | 786 kg |

Small business and household mills

Ideal for small business, catering trade and domestic use

Other than for the household, our mills are used:

• In hotel kitchens

• On breakfast buffets

• In organic shops

• In health food shops

Here you will find our range of products for mills for small business and domestic use.

You will find all the important information about our grain mills in this brochure. Presented there are our large commercial mills of the HM series as well as mills for small business.

We will be happy to send you a printed copy at no charge: