The Häussler-HABOMAT – innovative technology: Wood pellets

The firing of a wood-burning oven could be automated for the first time by using wood pellets. The firing can be started manually or automatically via a timer. The wood pellets are transported vie a screw conveyor into the combustion chamber and automatically ignited there. Now the heating process begins, during which the fireclay bricks are heated up to the set baking chamber temperature. All oven data are monitored and shown in the display for checking during the entire heating process. After reaching the set baking temperature, the oven signals visually and acoustically that it is ready for baking. The HABOMAT doesn’t require any staff deployment during this time, which saves on operating costs.

Benefits of the HABOMAT with eco-fire system

- Automatic firing

- Starting time, firing period and temperature can be pre-selected

- Acoustic signal indicates oven is ready for use

- Short residual heating phase for repeated baking

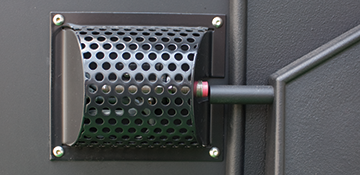

- Virtually residue-free combustion

- Glass insert in the door for visible fire

- Integrated maintenance programme

Baked goods from the HABOMAT can be sold as original wood-burning oven products!

Environmental consciousness that pays off:

Heating with wood pellets reduces the greenhouse effect, since pellets behave during combustion in a CO2 neutral way, which means they give off previously stored solar energy without increasing the CO2 content of the atmosphere. Furthermore, the pellets come to us at short distances from domestic production. They therefore help to save energy during production and delivery. Pellets perform very well compared to other fuels in a comparison of energy costs. Anyone who pays attention to trends in politics and the economy can assume that fossil fuels (oil/gas) are going to get increasingly expensive in the future.

Advantages that only Häussler offers:

- Short heating times: cold start only about 3 hours, warm start only about 45 minutes.

- Uniform baking result in the whole oven – no re-loading of the baked goods necessary!

- Short installation time and everything from a single source – the HABOMAT is ready to use within only 2 - 3 days after delivery.

- Can be flexibly relocated.

- Type-tested according to:

- DIN 18880

- Machinery directive

- Low-voltage directive - Loading height can be changed on request.

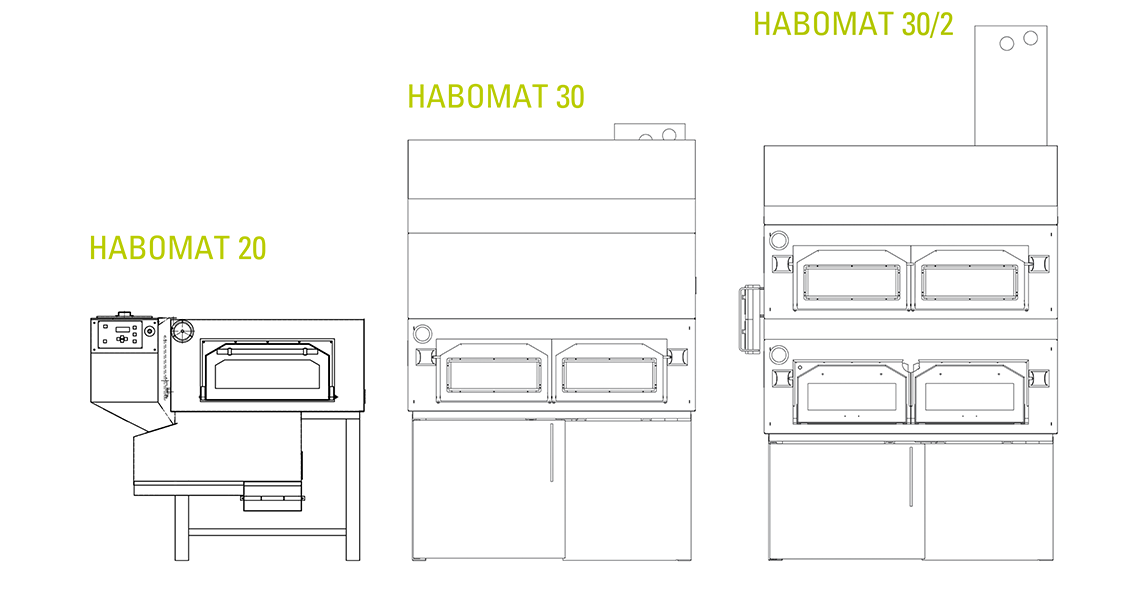

HABOMAT 20 - The little one with power

Thanks to its modest exterior dimensions and its remarkable baking surface of 1.4 m², the HABOMAT 20 is ideally suited for use in the sales area of your bakery or branch store. The large display facilitates easy operation and can also be installed outside of the field of view. The pellet container can be installed on request right or left.

Cladding

The HABOMAT’s cladding is simple, economical and effective! On request, we will deliver the oven to you with a frame for the cladding.

The HABOMAT 20 in brief:

- Baking surface 1.4 m²

- Capacity 28 loaves of bread (750 g)

- Can be combined with LABOMAT

- Firing from the rear of the oven

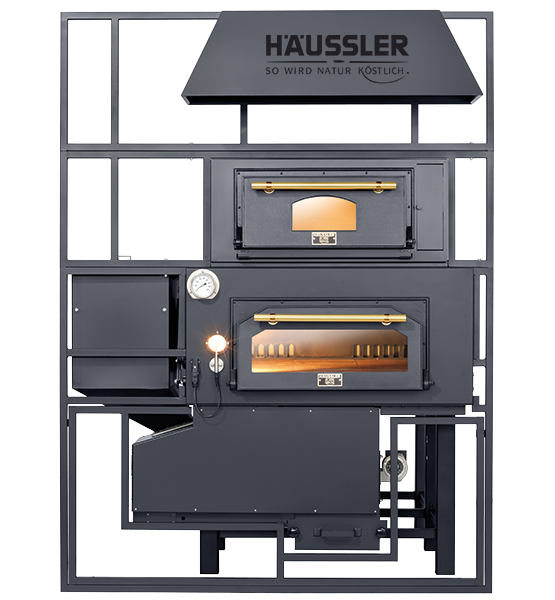

HABOMAT 30 - the big one for production

The advantages of the HABOMAT 30 from HÄUSSLER are obvious: With a total baking surface of 2.73 m², it is the “big brother” of the successful HABOMAT 20. Consequently it is the ideal production oven as well as a show oven at any given time in shopping arcades thanks to its elegant appearance, or it can be used in glassed-in production. The oven comes in one or two tiers. It can be flexibly set up and disassembled and relocated within only a few hours. The HABOMAT is delivered complete and ready to use, so that it can be integrated into your workflow without additional expense and quickly begin production.

The HABOMAT 30 in brief:

- Baking surface 2.73 m²

- Capacity 55 loaves of bread (750 g)

- Available as a two-tier version

- Firing from the rear of the oven

Details that are decisive

HABOMAT series at a glance – the right oven size for every need

Technical data

| Automated wood-burning oven | HABOMAT 20 | HABOMAT 30 | HABOMAT 30/2 |

| Baking surface W x D | 90 x 155 cm | 130 x 210 cm | 2 x 130 x 210 cm |

| Baking surface in m² | 1.39 m² | 2.73 m² | 2 x 2.73 m² = 5.46 m² |

| Baking chamber height | 30 cm | 30 cm | 30 cm |

| Exterior dimensions | 164 x 226 x 144 cm | 171 x 354 x 260 cm | 171 x 354 x 311 cm |

| Loading height | 100 cm | 100 cm | 85 cm / 152 cm |

| Weight | 1500 kg | 2600 kg | 4800 kg |

Firing heat output | 34 kW | 75 kW | 150 kW |

| Fuel | Wood pellets | Wood pellets | Wood pellets |

| Pellet consumption, cold start | 20 kg | 30 kg | 60 kg |

| Pellet consumption, warm start | 10 kg | 12 kg | 24 kg |

| Flue pipe connection Ø | 15 cm | 18 cm | 22.5 cm |

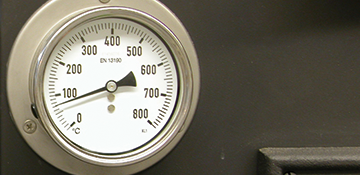

| Temperature range | up to 360 °C | up to 360 °C | up to 360 °C |

| Power consumption | 0.81 A | 1.78 A | 2 x 1.78 A |

| Power connection | 230 V | 230 V | 2 x 230 |

| Capacity, mixed bread approx. 750 g |

HABOMAT meets LABOMAT

A good combination: LABOMAT 9000 with Häussler HABOMAT 20

Many bakers choose the HABOMAT wood-burning oven in addition to our LABOMAT 9000 electric stone oven. In this way, bread and baked goods that are baked for a short period are produced in an optimum interaction. At the same time, the bread produced in the HABOMAT can be sold as bread baked in an original wood-burning oven. With the HABOMAT 20, the nostalgic glass door allows a view of the blazing flames.

The innovative technology: an automated wood-burning oven with eco-fire system

The firing of a wood-burning oven could be automated for the first time by using wood pellets. The firing can be started at the touch of a button or via a program. The wood pellets are transported vie a screw conveyor into the combustion chamber and ignited there. Now the heating process begins. The fireclay bricks are heated up to the set baking temperature. All oven data are monitored and shown in the display for checking during the entire heating process. After reaching the set baking temperature, the oven signals visually and acoustically that it is ready for baking. The HABOMAT doesn’t require any staff deployment during this time, which saves on operating costs.

Baking with the LABOMAT-HABOMAT combination:

- Economical in terms of operating and energy costs.

- Low personnel costs

- Optimum interaction: Bread baked from a wood-burning oven from the HABOMAT and small baked goods from the LABOMAT

- Ideal front baking combination as show bake oven and high-performance production oven

- Nostalgic design

- Profitable combination in looks and quality

- Clean, environmentally friendly and low-maintenance

- Baked goods from the HABOMAT can be sold as original wood-burning oven products

You will find everything about the world of the wood-burning oven in our brochure. Presented there is not only the HABOMAT pellet oven, but also the HABO series, wood-burning oven kits, the DEBO continuous wood-burning oven and our BakeMobiles. The correct marketing for using a wood-burning oven is also explained.

We will be happy to send you a printed copy at no charge: